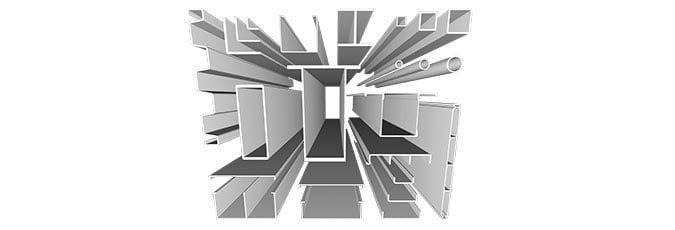

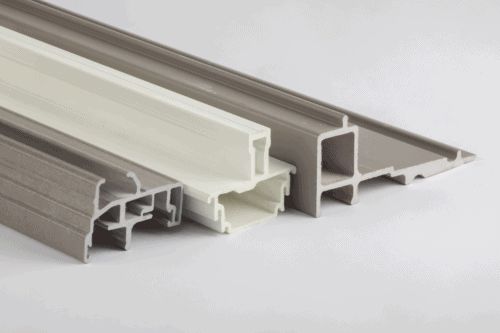

Frp Profile Pultruded

WELLGRID waa lamaanahaaga injineernimada ee FRP tareen-gacmeedka, biraha ilaalinta, jaranjarada iyo baahiyaha wax soo saarka. Kooxdayada xirfadlayaasha injineernimada iyo qorista ayaa kaa caawin kara inaad hesho xalka saxda ah ee buuxinaya baahiyahaaga cimri dherer, badbaado iyo kharash.

Astaamaha

Fudud ilaa miisaan

Pound-for-pound, Qaabab dhismeedkeena fiberglass-ka-jiifka ah ayaa ka xoog badan birta jihada dhererka ah. FRP-geena ayaa miisaankeedu yahay ilaa 75% in ka yar birta iyo 30% ka yar aluminium - ku haboon marka miisaanka iyo waxqabadka la tiriyo.

Rakibaadda fudud

FRP waxay ku kacaysaa celcelis ahaan 20% ka yar birta in lagu rakibo wakhti yar, qalab yar, iyo shaqaale khaas ah oo yar. Ka fogow shaqada khaaska ah ee qaaliga ah iyo qalabka culus, oo dedeji habka dhismaha adoo isticmaalaya alaab dhismeed oo jeexan.

Daxalka Kiimikada

Isku-dhafka Fiber-ka ee la xoojiyay (FRP) waxay bixiyaan iska caabin kiimikooyin badan oo kala duwan iyo deegaan qallafsan. Waxaan bixinaa hagaha iska caabbinta daxalka oo buuxa si loo hubiyo waxqabadka alaabteeda qaar ka mid ah xaaladaha ugu adag.

Dayactirka bilaashka ah

FRP waa mid waara oo u adkaysata saamaynta. Uma jabi doono ama uma ekaan doono sida biraha. Waxay u adkaysataa qudhunka iyo daxalka, isaga oo meesha ka saaraya baahida dayactirka joogtada ah. Isku dhafkan waxqabadka iyo cimri dhererka ayaa bixiya xalka ugu fiican ee codsiyo badan.

Cimri dheer oo adeeg

Badeecadahayadu waxay bixiyaan adkeysi heer sare ah iyo iska caabin daxalka ah ee codsiyada dalbanaya, iyagoo siinaya nolol wax soo saar oo ka wanaagsan agabka dhaqameed. Cimriga dheer ee alaabta FRP waxa ay bixisaa kayd kharash ah inta lagu jiro wareegga nolosha ee alaabta. Kharashyada la rakibay way yar yihiin sababtoo ah fududaynta rakibidda. Kharashaadka dayactirku wuu yareeyaa sababtoo ah waxaa yaraaday wakhtiga meelaha u baahan dayactirka, iyo kharashyada qaadista, tuurista, iyo bedelida shabagyada birta ah ee daxalaystay waa la tirtiray.

Xoog Sare

FRP waxay leedahay saami xoog iyo miisaan sare leh marka la barbar dhigo agab dhaqameedka sida birta, shubka iyo alwaax. Xirmooyinka FRP waxaa loo qaabayn karaa inay noqdaan kuwo xoog badan oo qaadi kara culaysyada baabuurta iyadoo weli ay ka yar tahay nus culayska shaadhka birta.

Resistant Resistant

FRP waxay u adkeysan kartaa saameynaha waaweyn oo leh burbur aan muuqan. Waxaan bixinaa shahaado aad u raagaya si aan u qancino xitaa shuruudaha saamaynta ugu adag.

Koronto ahaan & Kuleyl Aan Dhaqan Lahayn

FRP waa koronto ahaan mid aan tabo lahayn taasoo horseedaysa badbaado korodhay marka la barbar dhigo qalabka wax dhaqaajiya (ie, biraha). FRP waxay sidoo kale leedahay kulaylka kuleylka hooseeya (wareejinta kulaylku waxay ku dhacdaa heer hoose), taasoo keentay dusha alaabta raaxada leh marka taabashadu dhacdo.

Dabdemiska

Alaabooyinka FRP waxaa loo naqshadeeyay inay yeeshaan faafitaanka ololka 25 ama ka yar sida lagu tijaabiyay si waafaqsan ASTM E-84. Waxay sidoo kale buuxiyeen shuruudaha is-daminta ee ASTM D-635.

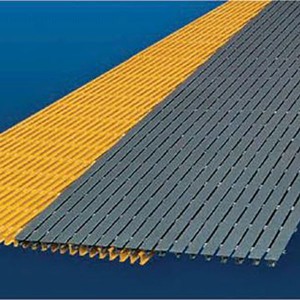

Iska caabin simbiriirix ah

Alaabtayada jaranjarada ee la jeexjeexay iyo kuwa jeexjeexan waxay ku siinayaan cag heer sare ah, simbiriirixan u adkaysta deegaanka qoyan iyo saliidda leh. Birtu waxay noqotaa mid sibiqsan marka ay saliid leedahay ama qoyan tahay, laakiin gogoshayadu waxay leeyihiin warshad xoqan oo sareysa waxayna ahaanayaan badbaado xitaa marka qoyan.

Alaabtayada simbiriirixiinta u adkaysta waxay kordhiyaan badbaadada shaqaalaha taasoo u horseedi doonta shilalka goobta shaqada oo yaraada iyo dhimista kharashyada la xidhiidha dhaawaca.

Tilmaamaha

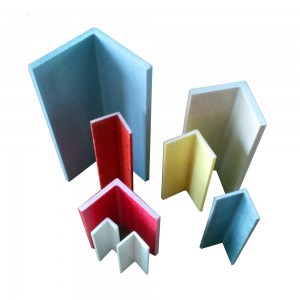

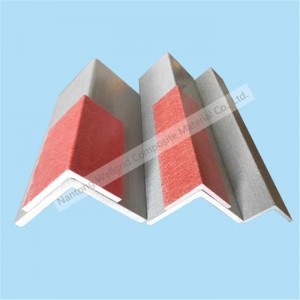

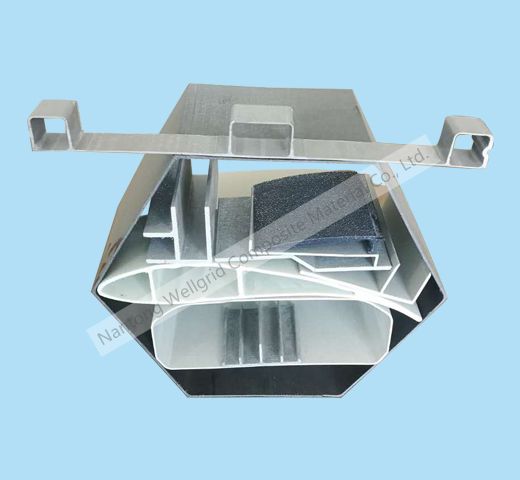

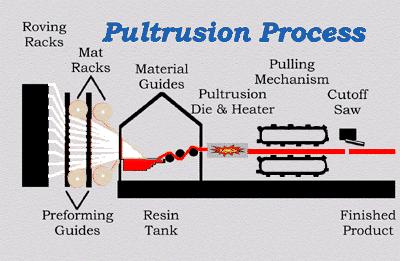

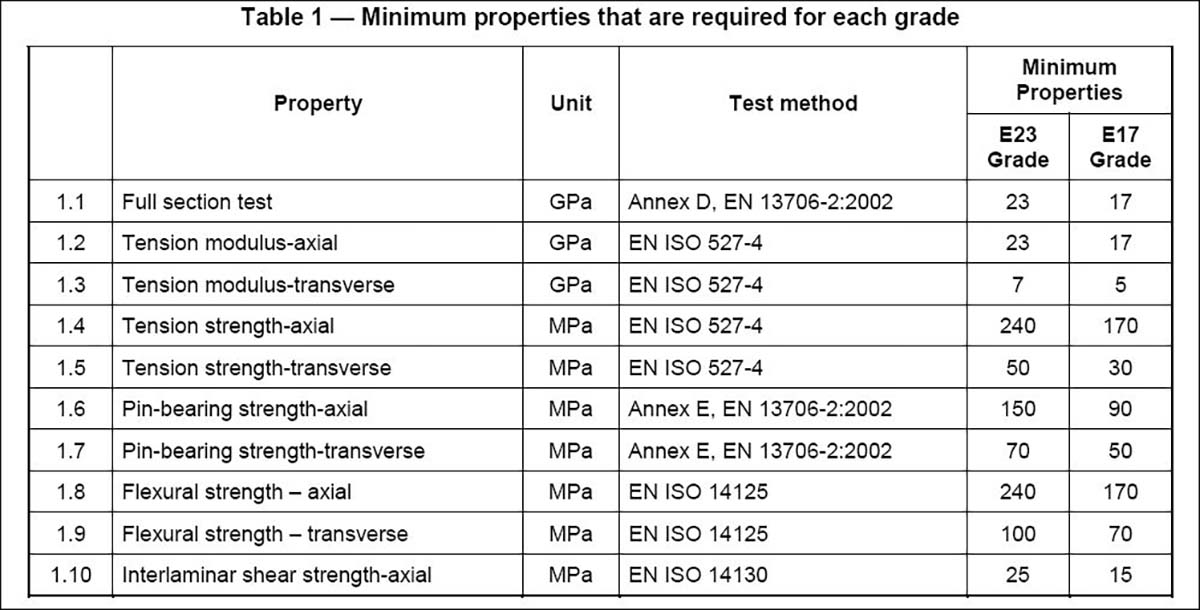

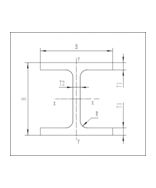

Qaababka qaab-dhismeedka pultrusion waxay leeyihiin awood sare iyo modules dherer ahaan (LW) iyo iskutallaab ahaan (CW) oo buuxiya heerarka Yurub iyo Ameerika ee khuseeya; waxaa si weyn loogu isticmaalaa dibadda munaaradda qaboojinta, warshadaha korontada. Fadlan nala soo xidhiidh si aad u heshid tafaasiil ku saabsan qaab-dhismeedka pultrusion.

Waxaan bixinaa muuqaalada qaabdhismeedka FRP pultrusion oo buuxiya heerka EN 13706 oo leh hanti hoose.

| Xagasha | H (mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 25 | 25 | 3.2 | 3.2 | 153 | 290 | |

| 30 | 20 | 4 | 4 | 184 | 350 | |

| 30 | 30 | 3 | 3 | 171 | 325 | |

| 40 | 22 | 4 | 4 | 232 | 440 | |

| 40 | 40 | 4 | 4 | 304 | 578 | |

| 40 | 40 | 8 | 8 | 574 | 1090 | |

| 50 | 50 | 5 | 5 | 475 | 902 | |

| 50 | 50 | 6.4 | 6.4 | 604 | 1147 | |

| 76 | 76 | 6.4 | 6.4 | 940 | 1786kii | |

| 76 | 76 | 9.5 | 9.5 | 1367 | 2597 | |

| 101 | 101 | 6.4 | 6.4 | 1253 | 2380 | |

| 101 | 101 | 9.5 | 9.5 | 1850kii | 3515 | |

| 101 | 101 | 12.7 | 12.7 | 2425 | 4607 | |

| 152 | 152 | 9.5 | 9.5 | 2815 | 5348 | |

| 152 | 152 | 12.7 | 12.7 | 3730 | 7087 | |

| 220 | 72 | 8 | 8 | 2274 | 4320 |

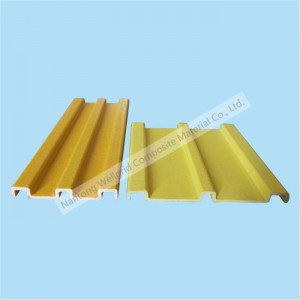

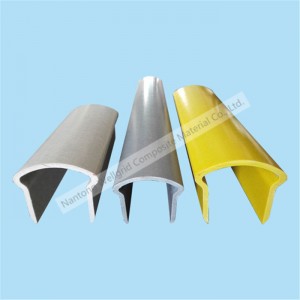

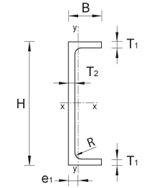

| Kanaalka | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

|

| 40 | 20 | 4 | 4 | 289 | 550 |

| 50 | 14 | 3 | 3 | 220 | 418 | |

| 75 | 25 | 5 | 5 | 576 | 1094 | |

| 76 | 38 | 6.4 | 6.4 | 901 | 1712 | |

| 80 | 30 | 3.1 | 3.1 | 405 | 770 | |

| 101 | 35 | 3.2 | 3.2 | 529 | 1006 | |

| 101 | 48 | 3.2 | 3.2 | 613 | 1165 | |

| 101 | 30 | 6.4 | 6.4 | 937 | 1780kii | |

| 101 | 44 | 6.4 | 6.4 | 1116 | 2120 | |

| 150 | 50 | 6 | 6 | 1426 | 2710 | |

| 152 | 35 | 4.8 | 4.8 | 1019 | 1937kii | |

| 152 | 48 | 4.8 | 4.8 | 1142 | 2170 | |

| 152 | 42 | 6.4 | 6.4 | 1368 | 2600 | |

| 152 | 45 | 8 | 8 | 1835kii | 3486 | |

| 152 | 42 | 9.5 | 9.5 | 2077 | 3946 | |

| 178 | 60 | 6.4 | 6.4 | 1841kii | 3498 | |

| 203 | 55 | 6.4 | 6.4 | 1911kii | 3630 | |

| 203 | 55 | 9.5 | 9.5 | 2836 | 5388 | |

| 254 | 72 | 12.7 | 12.7 | 4794 | 9108 |

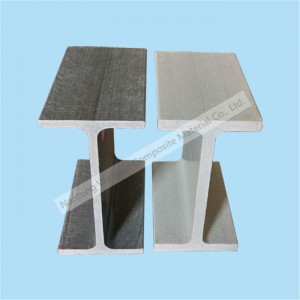

| Waxaan ahay Beam | H (mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 25 | 15 | 4 | 4 | 201 | 381 |

| 38 | 15 | 4 | 4 | 253 | 480 | |

| 50 | 15 | 4 | 4 | 301 | 571 | |

| 76 | 38 | 6.4 | 6.4 | 921 | 1749kii | |

| 102 | 51 | 6.4 | 6.4 | 1263 | 2400 | |

| 152 | 76 | 6.4 | 6.4 | 1889kii | 3590 | |

| 152 | 76 | 9.5 | 9.5 | 2800 | 5320 | |

| 203 | 101 | 9.5 | 9.5 | 3821 | 7260 | |

| 203 | 101 | 12.7 | 12.7 | 5079 | 9650 | |

| 254 | 127 | 9.5 | 9.5 | 4737 | 9000 | |

| 254 | 127 | 12.7 | 12.7 | 6289 | 11950kii | |

| 305 | 152 | 9.5 | 9.5 | 5653 | 10740 | |

| 305 | 152 | 12.7 | 12.7 | 7526 | 14300 |

| WFB Beam | H (mm) | B(mm) | T1(mm) | T2(mm) | (mm²) | (g/m) |

| 76 | 76 | 6.4 | 6.4 | 1411 | 2680 |

| 102 | 102 | 6.4 | 6.4 | 1907dii | 3623 | |

| 100 | 100 | 8 | 8 | 2342 | 4450 | |

| 152 | 152 | 6.4 | 6.4 | 2867 | 5447 | |

| 152 | 152 | 9.5 | 9.5 | 4250 | 8075 | |

| 203 | 203 | 9.5 | 9.5 | 5709 | 10847 | |

| 203 | 203 | 12.7 | 12.7 | 7558 | 14360 | |

| 254 | 254 | 9.5 | 9.5 | 7176 | 13634 | |

| 254 | 254 | 12.7 | 12.7 | 9501 | 18051kii | |

| 305 | 305 | 9.5 | 9.5 | 8684 | 16500 | |

| 305 | 305 | 12.7 | 12.7 | 11316 | 21500 |

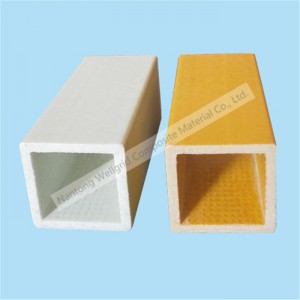

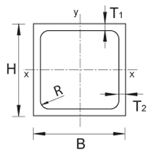

| Tuubo labajibbaaran | H (mm) | B (mm) | T1 (mm) | T2 (mm) | (mm²) | (g/m) |

| 15 | 15 | 2.5 | 2.5 | 125 | 237 | |

| 25.4 | 25.4 | 3.2 | 3.2 | 282 | 535 | |

| 30 | 30 | 5 | 5 | 500 | 950 | |

| 38 | 38 | 3.2 | 3.2 | 463 | 880 | |

| 38 | 38 | 6.4 | 6.4 | 811 | 1540 | |

| 40 | 40 | 4 | 4 | 608 | 1155 | |

| 40 | 40 | 6 | 6 | 816 | 1550 | |

| 44 | 44 | 3.2 | 3.2 | 521 | 990 | |

| 44 | 44 | 6.4 | 6.4 | 963 | 1830kii | |

| 45 | 45 | 4 | 4 | 655 | 1245 | |

| 50 | 25 | 4 | 4 | 537 | 1020 | |

| 50 | 50 | 4 | 4 | 750 | 1425 | |

| 50 | 50 | 5 | 5 | 914 | 1736 | |

| 50 | 50 | 6.4 | 6.4 | 1130 | 2147 | |

| 54 | 54 | 5 | 5 | 979 | 1860kii | |

| 60 | 60 | 5 | 5 | 1100 | 2090 | |

| 76 | 38 | 4 | 4 | 842 | 1600 | |

| 76 | 76 | 6.4 | 6.4 | 1795kii | 3410 | |

| 76 | 76 | 9.5 | 9.5 | 2532 | 4810 | |

| 101 | 51 | 6.4 | 6.4 | 1779kii | 3380 | |

| 101 | 76 | 6.4 | 6.4 | 2142 | 4070 | |

| 101 | 101 | 6.4 | 6.4 | 2421 | 4600 | |

| 101 | 101 | 8 | 8 | 2995 | 5690 | |

| 130 | 130 | 9 | 9 | 4353 | 8270 | |

| 150 | 150 | 5 | 5 | 2947 | 5600 | |

| 150 | 150 | 10 | 10 | 5674 | 10780 | |

| Tuubada wareega | D1 (mm) | D2 (mm) | T (mm) | (mm²) | (g/m) |

|

| 19 | 14 | 2.5 | 128 | 245 |

| 24 | 19 | 2.5 | 168 | 320 | |

| 25.4 | 20.4 | 2.5 | 180 | 342 | |

| 30 | 24 | 3 | 254 | 482 | |

| 32 | 26 | 3 | 273 | 518 | |

| 40 | 32 | 4 | 452 | 858 | |

| 50 | 42 | 4 | 578 | 1098 | |

| 50 | 40 | 5 | 707 | 1343 | |

| 50 | 37.2 | 6.4 | 877 | 1666 | |

| 65 | 52.2 | 6.4 | 1178 | 2220 | |

| 76 | 63.2 | 6.4 | 1399 | 2658 | |

| 101 | 85 | 8 | 2337 | 4440 |

| Wareeg adag | D (mm) | (mm²) | (g/m) | |

| 7 | 38 | 72 | |

| 8 | 50 | 95 | ||

| 10 | 79 | 150 | ||

| 12 | 113 | 215 | ||

| 15 | 177 | 336 | ||

| 18 | 254 | 483 | ||

| 20 | 314 | 597 | ||

| 25 | 491 | 933 | ||

| 38 | 1133 | 2267 | ||

| saxan laad | B(mm) | H(mm) | T(mm) | (mm²) | (g/m) |

| 100 | 12 | 3 | 461 | 875 |

| 100 | 15 | 4 | 579 | 1100 | |

| 150 | 12 | 3 | 589 | 1120 |